When it comes to vehicle maintenance, one aspect that often flies under the radar is the importance of lug nut torque. Proper torque on your vehicle’s wheel lug nuts is not just a technical specification; it’s a critical component of vehicle safety. This guide will delve into the essentials of lug nut torque, why it matters, and how to ensure your vehicle’s wheels are securely fastened.

- Understanding Lug Nut Torque

- Why Proper Torque Matters

- How to Measure and Adjust Lug Nut Torque

- Common Torque Values by Vehicle Type

- The Dangers of Neglecting Lug Nut Torque

- How to Establish a Routine for Lug Nut Torque Checks

- Understanding Specifications: More Than Just Numbers

- Professional Assistance: When to Call in the Experts

Understanding Lug Nut Torque

Lug nut torque refers to the amount of rotational force applied to the lug nuts that hold your wheels in place. Each vehicle manufacturer specifies a particular torque value, usually measured in foot-pounds (ft-lbs) or Newton-meters (Nm). This specification is crucial for several reasons:

- Safety: Properly torqued lug nuts ensure that your wheels remain securely attached during operation, preventing potentially dangerous situations such as wheel detachment.

- Even Wear: Correct torque helps in distributing the load evenly across the wheel hub, which minimizes wear and tear on both the lug nuts and the wheel itself.

- Performance: Vehicles perform better when the wheels are secured properly, enhancing handling and stability.

Why Proper Torque Matters

Many vehicle owners underestimate the significance of lug nut torque. Here are some critical points to consider:

- Over-Torquing: Applying excessive torque can lead to stripped threads, which may cause the lug nut to fail. This often results in costly repairs and, more importantly, poses a safety risk.

- Under-Torquing: Insufficient torque can lead to wheels becoming loose over time, particularly with the vibrations caused during driving. This can result in dangerous situations, including wheel separation.

How to Measure and Adjust Lug Nut Torque

Using a torque wrench is the gold standard for measuring lug nut torque. Here’s how to do it effectively:

- Gather Your Tools: You will need a torque wrench, a socket that fits your lug nuts, and potentially a breaker bar for loosening.

- Check the Manufacturer’s Specifications: Refer to your vehicle’s owner manual or the manufacturer’s guidelines to find the correct torque specification for your vehicle;

- Loosen and Tighten: If you are adjusting the torque, start by loosening each lug nut slightly before re-torquing them to the specified value.

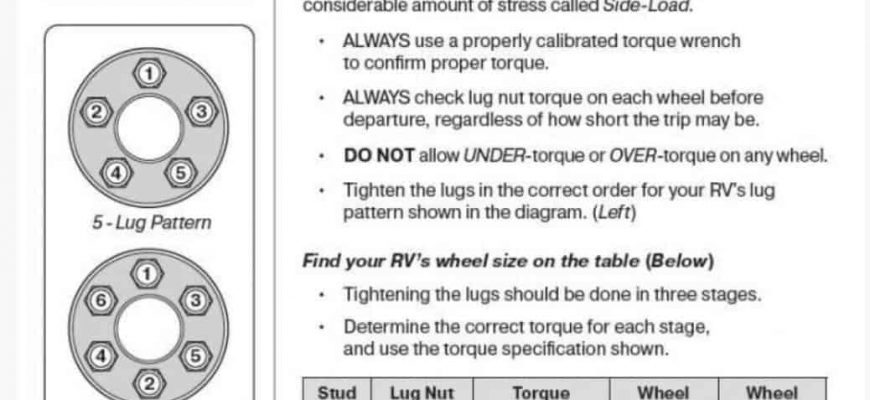

- Torque Pattern: Follow the proper tightening pattern (usually a star or criss-cross pattern) to ensure even distribution of pressure.

- Recheck After Driving: After driving for a short distance, it’s wise to recheck the torque to ensure nothing has loosened.

Common Torque Values by Vehicle Type

While it’s essential to consult your vehicle’s manual, here are some common torque values for various types of vehicles:

- Passenger Cars: 80-100 ft-lbs

- SUVs: 90-110 ft-lbs

- Trucks: 100-130 ft-lbs

- Performance Vehicles: 100-120 ft-lbs

Stay safe on the road, and remember: a little attention to detail today can prevent significant problems tomorrow!

In the realm of vehicle maintenance, the significance of lug nut torque cannot be stressed enough. While many drivers focus on oil changes, tire rotations, and brake checks, the lug nuts—those seemingly simple fasteners—play a crucial role in ensuring your safety on the road. Neglecting this aspect of vehicle care can lead to dire consequences, including accidents and costly repairs.

The Dangers of Neglecting Lug Nut Torque

Imagine cruising down the highway, music playing, when suddenly, you hear a disturbing sound. It’s the unmistakable clunk of a loose wheel. This scenario is more common than you might think and can often be traced back to improper lug nut torque. Here’s why you should never overlook this critical component:

- Wheel Detachment: Loose lug nuts can result in a wheel coming off while driving, leading to a loss of control and a potential crash.

- Tire Blowouts: Unevenly torqued lug nuts can cause tires to wear unevenly, increasing the risk of blowouts.

- Increased Repair Costs: If lug nuts are not properly secured, it can lead to additional wear on the brake rotors and wheel bearings, necessitating expensive repairs.

How to Establish a Routine for Lug Nut Torque Checks

Establishing a routine for checking lug nut torque is crucial for maintaining vehicle safety. Here’s a straightforward approach to incorporate this practice into your vehicle maintenance schedule:

- Frequency: Check lug nut torque every 5,000 miles or after any significant tire work (installing new tires, rotating tires, etc.).

- Tools Required: Invest in a quality torque wrench that allows you to accurately measure the torque. A click-type torque wrench is often recommended for its precision.

- Visual Inspection: During your check, visually inspect the lug nuts for rust or corrosion that may affect their integrity.

- Environment Matters: Keep in mind that environmental conditions can affect lug nut torque. If you frequently drive in extreme weather or off-road conditions, be more vigilant about checking.

Understanding Specifications: More Than Just Numbers

Every vehicle manufacturer provides specific torque specifications for lug nuts, typically found in the owner’s manual. However, understanding these numbers goes beyond simply following instructions:

- Thread Type: Different vehicles have different thread sizes and types, making it imperative to consult the manual and use the correct specifications.

- Material Matters: The material of both the lug nut and the wheel can affect how much torque is needed. Aluminum wheels, for example, may require a different torque setting than steel wheels.

Professional Assistance: When to Call in the Experts

While it’s beneficial to learn how to check and adjust lug nut torque yourself, there are times when professional assistance is warranted:

- Unusual Symptoms: If you notice your vehicle pulling to one side or hear strange noises from the wheels, consult a professional immediately.

- After Major Work: Following any significant repairs or tire replacements, having a mechanic check the lug nut torque can provide peace of mind.

Great guide! The explanation of the consequences of over-torquing and under-torquing was particularly helpful. I will definitely check my vehicle’s lug nut torque now.

This article is incredibly informative! I never realized how crucial lug nut torque is for vehicle safety. Thank you for shedding light on this often-overlooked topic!

This article is a must-read for all car owners! The insights on how to measure and adjust lug nut torque were very practical. Thanks for sharing!

I loved how you broke down the importance of proper torque in such a simple way. It’s a reminder that small details can make a big difference in safety!

Fantastic read! I appreciate the emphasis on using a torque wrench. It’s an essential tool that more drivers should be aware of when it comes to maintenance.